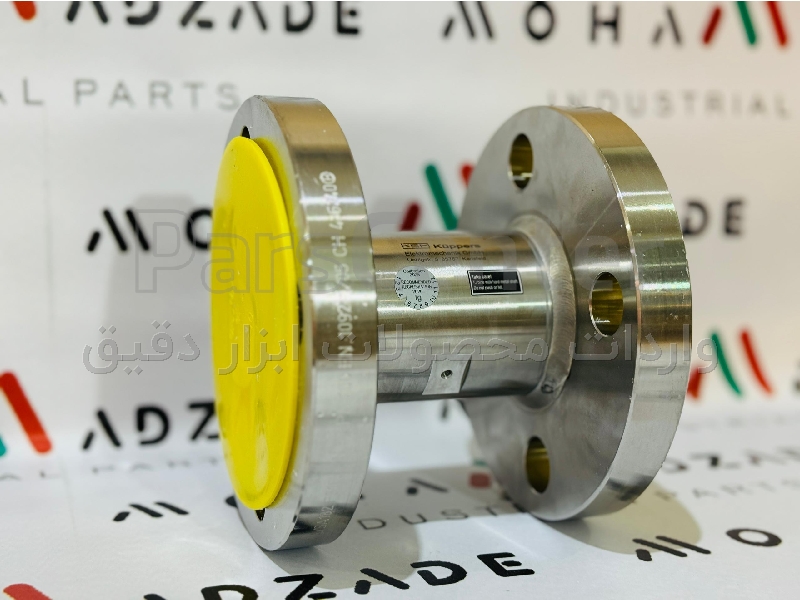

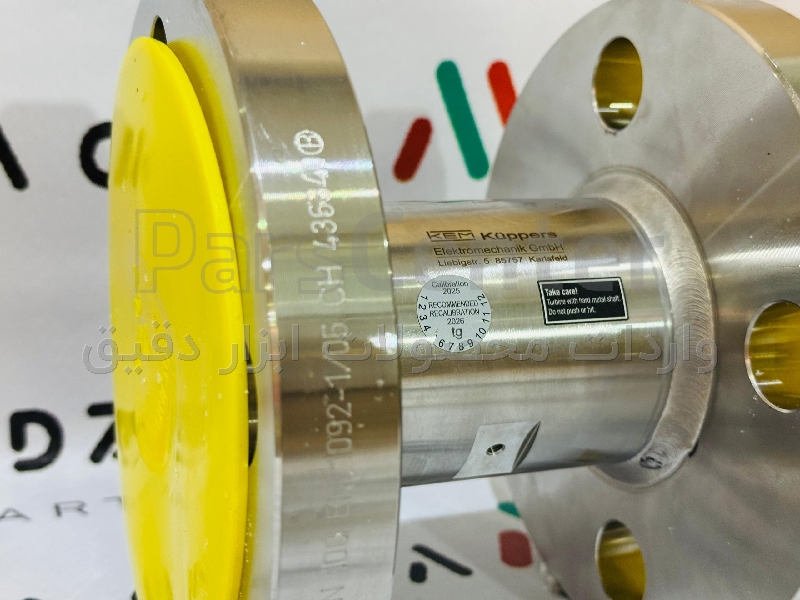

فلومتر توربینی KEM سری HM50 با اتصالات فلنجی

فلومتر توربینی KEM سری HM50 با اتصالات فلنجی ساخت کشور آلمان میباشد.فلومترهای سری HM F اغلب برای مایعات با ویسکوزیته کم و متوسط مانند آب، امولسیونها، مخلوطهای گلیکول و روغنهای سبک و عمدتاً برای سیالات روانکاری و غیر روانکاری بکار میروند. علاوه بر این فلومتر سایر محصولات برند KEM بصورت وارداتی تامین میگردد. جهت استعلام قیمت و موجودی با شرکت تماس حاصل فرمایید.

مشخصات

- شرکت سازنده :

- KEM

- مدل :

- HM50

- کشور سازنده :

- آلمان

- محدوده اندازهگیری :

- 20 bis 1,200 l/min

- فشار :

- 16 تا 250 بار [232 تا 3,626 psi]

فایلهای پیوست

| KEM HM_F_D_EN_250601_E001 | 3٫42 مگابایت | دانلود |

توضیحات محصول

The HM F turbine flow meter series (F for flange connections) is used to measure continuous and discontinuous flow rates. They are mainly used for lubrication and non-lubrication media. They are particularly suitable for low andmedium viscosity liquids, such as water, emulsions, glycol mixtures and lightoils.Only high-grade steels that can withstand corrosive liquids are used in theproduction of turbine flow meters. Combined with the use of tungsten carbidebearings, the HM F guarantees optimum measurement accuracy and an extremely long service life even under the toughest application conditions.The combination of various turbine wheel dimensions and blade geometriesallows a wide range of sizes that can cover a huge measuring range. Thismakes the HM F ideal for a variety of applications in the field of metering aswell as for monitoring, mixing and dosing.Short response times, very dynamic performance and high measurementaccuracy ensure accurate regulation and control of flow rates in the mostdemanding applications.For applications in hazardous areas, we offer intrinsically safe sensors andamplifiers with Ex protection in accordance with ATEX, IECEx, CSA and otherstandards. Additional certifications such as EAC (TR-CU) are available.Principle and DesignTurbine flow meters (HM) are volume counters operating on the Woltmannimpeller counter principle. They use the average flow velocity to record theflow rate through the pipeThe flow of the medium is directed at the turbine wheel in the axial directionand so rotated. The speed of the freely turning wheel over a wide range isdirectly proportional to the average flow velocity. The low weight of the turbinewheel ensures very short response times as well as very dynamic behaviourin flow changes. Two flow straighteners generate quasi-laminar flow, which inturn contributes to increasing the measurement accuracy.The speed of the turbine wheel is measured by the sensor through the housing wall. The sensor system can be selected to meet the requirements of theindividual application. This can provide, for example, a signal to indicate thedirection of flow.Pulses per unit of volume are available for analysis. The calibration factor(K-factor) of the flow meter describes the exact pulse rate per unit of volume.In order to determine the individual calibration factor of a flow meter, we calibrate each of our meters in house prior to delivery. The operating viscosityspecified by the customer is taken into account for calibration. A corresponding calibration certificate is included with every flow meter we supply.The KEM turbines feature a short response time between 5 and 50 msdepending on the nominal diameter, which is advantageous for precise fillingprocesses.Turbine flow meters have a resolution of up to 3,000 pulses per litre. Themilled and turned precision components are the reason why the HM serieshas neither wetted weld seams nor soldered connections. All market-relatedrequirements for piping and material standards can thus be fully guaranteed.