2015 ASME استاندارد ترک یاب مغناطیسی

ARTICLE 7

MAGNETIC PARTICLE EXAMINATION

T-710 SCOPE

When specified by the referencing Code Section, the

magnetic particle examination techniques described in

this Article shall be used. In general, this Article is in conformance

with SE-709, Standard Guide for Magnetic Particle

Examination. This document provides details to be

considered in the procedures used.

When this Article is specified by a referencing Code

Section, the magnetic particle method described in this

Article shall be used together with Article 1, General Requirements.

Definition of terms used in this Article are

in Article 1, Mandatory Appendix I, I-121.4, MT — Magnetic

Particle.

T-720 GENERAL

The magnetic particle examination method is applied to

detect cracks and other discontinuities on the surfaces of

ferromagnetic materials. The sensitivity is greatest for

surface discontinuities and diminishes rapidly with increasing

depth of discontinuities below the surface. Typical

types of discontinuities that can be detected by this

method are cracks, laps, seams, cold shuts, and

laminations.

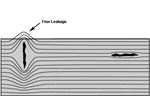

In principle, this method involves magnetizing an area

to be examined, and applying ferromagnetic particles (the

examination’s medium) to the surface. Particle patterns

form on the surface where the magnetic field is forced

out of the part and over discontinuities to cause a leakage

field that attracts the particles. Particle patterns are

usually characteristic of the type of discontinuity that is

detected.

Whichever technique is used to produce the magnetic

flux in the part, maximum sensitivity will be to linear discontinuities

oriented perpendicular to the lines of flux.

For optimum effectiveness in detecting all types of discontinuities,

each area is to be examined at least twice,

with the lines of flux during one examination being approximately

perpendicular to the lines of flux during the

other.

T-721 WRITTEN PROCEDURE REQUIREMENTS

T-721.1 Requirements. Magnetic particle examination

shall be performed in accordance with a written procedure,

which shall, as a minimum, contain the

requirements listed in Table T-721. The written procedure

shall establish a single value, or range of values,

for each requirement.

T-721.2 Procedure Qualification. When procedure

qualification is specified by the referencing Code Section,

a change of a requirement in Table T-721 identified as an

essential variable shall require requalification of the written

procedure by demonstration. A change of a requirement

identified as a nonessential variable does not

require requalification of the written procedure. All

changes of essential or nonessential variables from those

specified within the written procedure shall require revision

of, or an addendum to, the written procedure.

T-730 EQUIPMENT

A suitable and appropriate means for producing the

necessary magnetic flux in the part shall be employed,

using one or more of the techniques listed in and described

in T-750.

T-731 EXAMINATION MEDIUM

The finely divided ferromagnetic particles used for the

examination shall meet the following requirements.

(a) Particle Types. The particles shall be treated to impart

color (fluorescent pigments, nonfluorescent pigments,

or both) in order to make them highly visible

(contrasting) against the background of the surface being

examined.

(b) Particles. Dry and wet particles and suspension vehicles

should be in accordance with SE-709.

(c) Temperature Limitations. Particles shall be used

within the temperature range limitations set by the manufacturer

of the particles. Alternatively, particles may be

used outside the particle manufacturer’s recommendations

providing the procedure is qualified in accordance

with Article 1, T-150 at the proposed temperature.

T-740 MISCELLANEOUS REQUIREMENTS

T-741 SURFACE CONDITIONING

T-741.1 Preparation.

(a) Satisfactory results are usually obtained when the

surfaces are in the as-welded, as-rolled, as-cast, or asforged

conditions. However, surface preparation by

grinding or machining may be necessary where surface irregularities

could mask indications due to discontinuities

Table T-721

Requirements of a Magnetic Particle Examination Procedure

Requirement Essential Variable

Nonessential

Variable

Magnetizing technique X . . .

Magnetizing current type or amperage outside range specified by this Article or as previously

qualified

X . . .

Surface preparation X . . .

Magnetic particles (fluorescent/visible, color, particle size, wet/dry) X . . .

Method of particle application X . . .

Method of excess particle removal X . . .

Minimum light intensity X . . .

Existing coatings, greater than the thickness demonstrated X . . .

Nonmagnetic surface contrast enhancement, when utilized X . . .

Performance demonstration, when required X . . .

Examination part surface temperature outside of the temperature range recommended by the

manufacturer of the particles or as previously qualified

X . . .

Shape or size of the examination object . . . X

Equipment of the same type . . . X

Temperature (within those specified by manufacturer or as previously qualified) . . . X

Demagnetizing technique . . . X

Post-examination cleaning technique . . . X

Personnel qualification requirements . . . X

(b) Prior to magnetic particle examination, the surface

to be examined and all adjacent areas within at least

1 in. (25 mm) shall be dry and free of all dirt, grease, lint,

scale, welding flux and spatter, oil, or other extraneous

matter that could interfere with the examination.

(c) Cleaning may be accomplished using detergents, organic

solvents, descaling solutions, paint removers, vapor

degreasing, sand or grit blasting, or ultrasonic cleaning

methods.

(d) If nonmagnetic coatings are left on the part in the

area being examined, it shall be demonstrated that indications

can be detected through the existing maximum coating

thickness applied. When AC yoke technique is used,

the demonstration shall be in accordance with Mandatory

Appendix I of this Article.

T-741.2 Nonmagnetic Surface Contrast Enhancement.

Nonmagnetic surface contrasts may be applied by

the examiner to uncoated surfaces, only in amounts sufficient

to enhance particle contrast. When nonmagnetic

surface contrast enhancement is used, it shall be demonstrated

that indications can be detected through the enhancement

. Thickne s s measurement o f t h i s

nonmagnetic surface contrast enhancement is not

required.

NOTE: Refer to T-150(a) for guidance for the demonstration required

in T-741.1(d) and T-741.2.

T-750 TECHNIQUE

T-751 TECHNIQUES

One or more of the following five magnetization techniques

shall be used:

(a) prod technique

(b) longitudinal magnetization technique

(c) circular magnetization technique

(d) yoke techniquek.