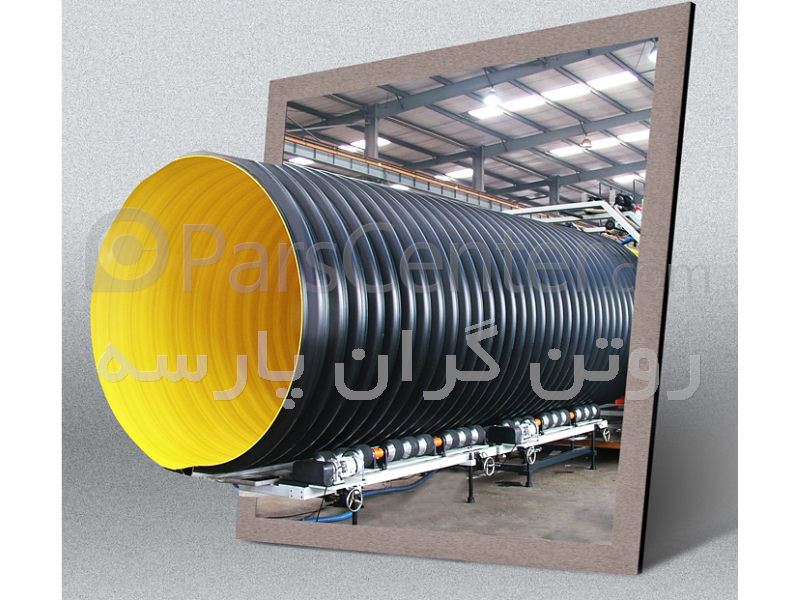

ُSpiral corrugate HDPE Pipe

مشخصات

- شرکت سازنده :

- روتنگران پارسه

- مدل :

- پلی اتیلن

- کشور سازنده :

- ایران

- SPIRAL :

- 200

- SPIRAL PIPE :

- 250

- SPIRAL PIPE :

- 315

- SPIRAL PIPE :

- 400

- SPIRAL PIPE :

- 800

- SPIRAL PIPE :

- 1000

- SPIRAL PIPE :

- 1200

- SPIRAL PIPE :

- 1500

- لوله :

- پلی اتیلن

- لوله :

- اسپیرال

- لوله :

- مانیسمان

- لوله :

- 250

قیمت محصول

- قیت همکار / عمده فروشی :

- استعلام قیمت

توضیحات محصول

Some characteristics of corrugated and Spiral Pipes

1. This pipe size is manufactured from 200mm to 3200mm.

2. These pipes are manufactured in accordance to DIN 16961, ISIR 91216, and EN 13476-3 standards.

3. Joints are produced in accordance to DVS 2207, DVS 2209 standards.

4. High longevity

5. Resistant to chemicals, acids, and bases

6. Resistant to ultraviolet ray/radiation

7. Resistant to physical stress and shocks

8. Low coarseness / roughness coefficient

9. Easy transportation

Applications of Spiral Pipes:

1. Construction of polyethylene bridges

2. Transfer of water and sewage fluids

3. Transfer of acids and bases

Concerning installation conditions, calculation method, and flexibility, polyethylene bridges are more important than steel concrete bridges.

To install polyethylene bridges, observation of the following points are essential:

• Trench width should comply with external diameter and the soil behind pipes should be beaten. Trench width surely needs to be selected in the minimum allowable degree, and it should be avoided from unwelcome replacement. So, the more is the trench width, the more is soil pressure on the bridge.

• The trench should be prevented from getting wet and soaked during the operation of the bridge installation.

• For pipe installation, the inside of the trench should be free of any stones and sharp particles, and if the trench floor is not appropriate for pipe laying, suitable amended and screened soil needs to be applied. The soil behind the pipe should be beaten. Proper beating of soil by the bridge will help its strength.

• Bedding is considered as one of the essential factors in the bridge installation, and it is also like a soft support for the bridge. To provide a bed, no hard materials like concrete or cement should be used, and preferably clay is applied.

• Backband is another major factor bearing vertical forces caused by traffic loads and soil. Also, soil beating is a main factor that should be performed by observing principles and backband soil should be beaten at least up to 90%.

•Earth-filling is one of the factors that protects the bridge from stones and destructive components. Earth-filling height must be at least 30 cm above crown, and for earth-filling, coarse grains should be used.

WWW.ROTHENGARAN.COM

009832701094